Mastering Industrial Control: Integrating Modbus TCP/RTU Devices with Home Assistant

NGC 224

DIY Smart Home Creator

Unlocking Industrial-Grade Control: Integrating Modbus with Home Assistant

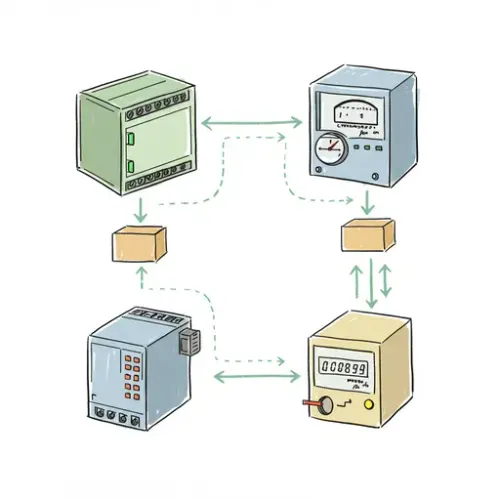

Are you looking to integrate industrial-grade devices—such as PLCs, advanced HVAC systems, specialized energy meters, or even legacy building automation equipment—into your Home Assistant ecosystem? If your smart home ambitions extend beyond consumer-grade gadgets, Modbus is the protocol you need to master. While often associated with industrial automation, Modbus is a robust, widely adopted, and surprisingly approachable standard for communicating with a vast array of hardware. The challenge lies not just in connecting, but in correctly interpreting and manipulating data to create actionable insights and automations in Home Assistant.

This guide dives deep into integrating Modbus TCP and Modbus RTU devices with Home Assistant, moving beyond theoretical concepts to provide practical, actionable steps. We'll cover everything from initial setup and register mapping to advanced configurations and troubleshooting, empowering you to bring the reliability and precision of industrial control into your personalized smart home environment.

Step-by-Step Setup: Connecting Your Modbus Devices

Integrating Modbus devices requires understanding your hardware's capabilities (Modbus TCP over Ethernet or Modbus RTU over serial like RS485) and the specific Modbus register maps provided by the device manufacturer. Always consult your device's manual for register addresses, data types, and access permissions (read/write).

Step 1: Prerequisites & Network Configuration

For Modbus TCP: Ensure your Modbus TCP device is connected to your local network and has a static IP address. Note down its IP address and the Modbus port (default is 502).

For Modbus RTU (over RS485): You'll need an RS485-to-Ethernet gateway (e.g., USR-TCP232-410S) or a USB-to-RS485 adapter connected to your Home Assistant host (if running Home Assistant OS/Supervised). The gateway method is generally preferred for stability and network accessibility. Configure your gateway to convert serial data to TCP, noting its IP, port, and the serial parameters (baud rate, data bits, stop bits, parity) that match your Modbus RTU device.

Step 2: Adding the Modbus Integration to Home Assistant

Modbus configuration is done directly in your configuration.yaml or through dedicated YAML files included via !include directives. Home Assistant's Modbus integration supports both TCP and RTU.

Modbus TCP Configuration Example:

# configuration.yaml

modbus:

- name: my_modbus_tcp_device

type: tcp

host: 192.168.1.100 # IP address of your Modbus TCP device

port: 502

sensors:

- name: Device Temperature

slave: 1 # Modbus slave ID, often 1

address: 40001 # Holding Register address

input_type: holding

unit_of_measurement: "°C"

data_type: int16 # Consult device manual for data type

scale: 0.1 # Example: if register value 250 means 25.0°C

precision: 1

scan_interval: 10 # Poll every 10 seconds

- name: Device Status

slave: 1

address: 1 # Coil address

input_type: coil

data_type: bool

scan_interval: 5

switches:

- name: Device Control Relay

slave: 1

address: 2 # Coil address to write to

write_type: coil

Modbus RTU over TCP (via Gateway) Configuration Example:

# configuration.yaml

modbus:

- name: my_modbus_rtu_device

type: rtuovertcp

host: 192.168.1.101 # IP address of your RS485-to-Ethernet gateway

port: 8899 # Port configured on your gateway

sensors:

- name: Energy Meter kWh

slave: 2 # Modbus slave ID for RTU device

address: 30005 # Input Register address

input_type: input

unit_of_measurement: "kWh"

data_type: float32 # Often for energy meters

count: 2 # float32 typically uses 2 registers

# byte_order: low_word_first # Or high_word_first, check device manual

scan_interval: 30

Key Modbus Parameters Explained:

name: A friendly name for your Modbus connection or entity.type:tcp,rtuovertcp, orserial(for direct USB-RS485).host&port: IP address and port of your Modbus server or gateway.slave: The Modbus address of the specific device on the bus (0-255).address: The register address to read/write. Modbus addresses are often 0-indexed in the protocol but device manuals might list them as 1-indexed (e.g., 40001 refers to address 0 in holding registers). Always subtract 1 from 1-indexed addresses.input_type:holding,input(for registers),coil, ordiscrete_input.data_type: Specifies how to interpret the raw bytes (int16,uint16,int32,uint32,float16,float32,string,bool).count: Number of registers to read for multi-register data types (e.g.,float32needs 2 16-bit registers).scale,offset: For converting raw register values to meaningful units.byte_order: Crucial for multi-register data types (e.g.,float32). Can below_word_first,high_word_first,low_byte_first,high_byte_first.scan_interval: How frequently Home Assistant polls the device.

After saving your configuration, restart Home Assistant to apply the changes.

Troubleshooting Common Modbus Integration Issues

Modbus can be finicky. Here are common problems and how to tackle them:

1. Device Not Responding / Entities Unavailable

- Network Connectivity: Ping your Modbus TCP device or gateway IP. If no response, check cables, power, and network settings.

- Port/Host Mismatch: Double-check the

hostandportin your HA configuration against your device/gateway settings. - Slave ID: Ensure the

slaveID in HA matches the device's configured Modbus ID. This is especially common for RTU devices on a bus. - Serial Parameters (RTU): For RTUoverTCP gateways, verify that the baud rate, data bits, stop bits, and parity on the gateway match your RTU device exactly.

- Device Health: Use a dedicated Modbus master tool (like Modbus Poll for Windows or QModMaster for Linux/Mac) to connect directly to your device/gateway. If these tools can't read data, the issue is with the device or network, not Home Assistant.

2. Incorrect Sensor Values / Data Corruption

- Register Address: This is the most frequent culprit. Modbus addresses are confusing. If your manual states 40001 (1-indexed holding register), use

address: 0andinput_type: holding. If it states 30001 (1-indexed input register), useaddress: 0andinput_type: input. Always check if the manual's addresses are 0-indexed or 1-indexed and adjust accordingly. - Data Type & Count: Incorrect

data_type(e.g., expectingint16but it'sfloat32) or wrongcount(e.g.,float32needs 2 registers). - Byte Order: For multi-register data types (

float32,int32), an incorrectbyte_order(low_word_firstvs.high_word_first;low_byte_firstvs.high_byte_first) will result in garbage values. Experiment with the different options if the manual isn't clear. - Scale/Offset: Verify these values if your raw register data requires scaling or an offset to represent the actual physical quantity.

3. Write Operations Failing (Switches)

- Read/Write Permissions: Some Modbus registers are read-only. Ensure the coil/register you're trying to write to is actually writable.

- Write Type: Confirm

write_type(coilorholding) matches the device's expectation.

Advanced Configuration & Optimization

1. Optimizing Polling Frequency and Grouping

Frequent polling can burden your Modbus network or device. Group registers that need to be read at the same frequency. If a device has many registers, consider polling less critical ones less frequently using different Modbus configurations or by adjusting scan_interval for individual sensors. Home Assistant's Modbus integration automatically groups contiguous registers for efficiency, but thoughtful organization helps.

For example, temperature sensors might need 10-second updates, while energy consumption aggregates can be every 30-60 seconds.

2. Handling Unavailable States Gracefully

If a Modbus device temporarily becomes unavailable, Home Assistant entities will show as 'unavailable'. You can use value_template with `is_state('unavailable')` or `is_number` checks to prevent automations from triggering on invalid data or to set default values.

# Example: Using value_template to handle potential unavailability

sensors:

- name: Robust Device Temperature

slave: 1

address: 40001

input_type: holding

unit_of_measurement: "°C"

data_type: int16

scale: 0.1

precision: 1

scan_interval: 10

value_template: >

{% if value is not none and value | is_number %}

{{ value }}

{% else %}

# Log or use a default value if needed, but 'none' propagates unavailable state

{% set value = states('sensor.robust_device_temperature') %} # Use last known good value

{% if value is not none and value != 'unavailable' %}

{{ value | float }}

{% else %}

unknown # Or 'unavailable' which is default for failing Modbus reads

{% endif %}

{% endif %}

3. Combining Multiple Registers for Complex Values

Sometimes a single physical value is split across multiple Modbus registers (e.g., 64-bit integers or custom packed data). You might need to read multiple separate registers and then use a Home Assistant Template Sensor to combine them into a single entity.

# configuration.yaml

modbus:

- name: my_modbus_device_split

type: tcp

host: 192.168.1.100

port: 502

sensors:

- name: Large Value Part 1

slave: 1

address: 40010

input_type: holding

data_type: uint16

scan_interval: 30

- name: Large Value Part 2

slave: 1

address: 40011

input_type: holding

data_type: uint16

scan_interval: 30

# template.yaml (or directly in configuration.yaml)

template:

- sensor:

- name: Combined Large Value

unit_of_measurement: "units"

state:

"{{ (states('sensor.large_value_part_1') | int * 65536) + (states('sensor.large_value_part_2') | int) }}"

This example assumes a specific byte order where Part 1 is the most significant word. Adjust the math based on your device's documentation.

Real-World Example: Smart HVAC Control via Modbus

Consider integrating an industrial-grade HVAC system that exposes its parameters (room temperature, setpoint, fan speed, mode) via Modbus TCP. This setup allows Home Assistant to become a sophisticated building management system.

# modbus_hvac.yaml

modbus:

- name: hvac_controller

type: tcp

host: 192.168.1.150

port: 502

sensors:

- name: HVAC Room Temperature

slave: 1

address: 1000 # Holding register for current temp

input_type: holding

data_type: int16

scale: 0.1

precision: 1

unit_of_measurement: "°C"

scan_interval: 5

- name: HVAC Mode Read

slave: 1

address: 1001 # Holding register for current mode (0=Off, 1=Heat, 2=Cool)

input_type: holding

data_type: uint16

scan_interval: 10

switches:

- name: HVAC Power

slave: 1

address: 100 # Coil for power ON/OFF

write_type: coil

# More advanced: climate entity via Modbus

climate:

- name: Main HVAC Zone

slave: 1

target_temperature_address: 1002 # Holding register to write setpoint

target_temperature_multiplier: 0.1 # Example: 220 in register means 22.0°C

temperature_register: 1000 # Register for current temp (already defined as sensor)

operation_mode_register: 1001 # Register for operating mode

# Map HA modes to Modbus register values

modes:

"off": 0

"heat": 1

"cool": 2

"fan_only": 3 # Assuming Modbus supports a fan_only mode

min_temp: 18

max_temp: 28

temp_step: 0.5

precision: 0.1

This configuration creates a climate entity in Home Assistant, allowing you to control the HVAC system's setpoint, mode, and power directly from Lovelace, automations, or voice assistants. You can then integrate this with occupancy sensors, schedules, or external weather data for truly smart and energy-efficient climate control.

Best Practices & Wrap-up

1. Security Considerations

- Network Isolation: If possible, place Modbus TCP devices or gateways on a separate VLAN or network segment from your main home network. This limits potential exposure.

- Read-Only Access: Where feasible, configure your Home Assistant Modbus integration for read-only access to devices if you only need to monitor data and not control anything.

- Firewall Rules: Restrict Modbus port (502) access to only your Home Assistant instance's IP address.

2. Scalability and Reliability

- Organize Configuration: Use

!includedirectives to split your Modbus configurations into separate files (e.g.,modbus_hvac.yaml,modbus_energy.yaml) for better readability and management. - Dedicated Hardware: For large or critical Modbus networks, consider a dedicated Modbus gateway appliance rather than relying solely on USB adapters or software bridges.

- Error Logging: Monitor Home Assistant logs for Modbus communication errors (e.g., timeouts, invalid responses). This helps identify intermittent connection issues or device faults.

3. Documentation is Key

Modbus integration relies heavily on accurate register maps. Always keep comprehensive documentation of your Modbus devices, including their addresses, data types, scaling factors, and byte orders. Annotate your Home Assistant YAML configurations with comments to explain complex register mappings.

By mastering Modbus integration, you unlock a new dimension of control and monitoring within Home Assistant. This approach allows you to leverage robust industrial hardware, providing unparalleled precision, reliability, and scalability for your smart home, bridging the gap between consumer automation and professional building management systems.

NGC 224

Author bio: DIY Smart Home Creator